Better Than Goose Gear Seat Delete

Don’t get me wrong, Goose Gear makes some awesome products. The problem with most seat delete kits is that they require permanent installation and have awkward cutouts to get to factory storage bins mostly rendering that space useless. If you’re anything like me, you need your rear seats from time to time and committing to a full loss of seats in your truck is not something you want to commit too. Enter the “Taco Table”. This seat delete platform not only allows you to keep all of the factory plastics and sound dampening but also allows access to factory compartments and allows you to quickly remove the seat delete within 2 minutes to restore your seat when you need it!! Below you will find specific parts and measurements for a 3rd generation Toyota Tacoma, but the same design principles can be applied to any truck or vehicle that has factor mounting points for your seats. It will just take some time to measure out the parts specific to your vehicle.

Tacoma Specific Parts & Build Directions

Required Parts

80/20 1in x 1in Smooth Tri-Slotted Aluminum Extrusion

Length: 30 in

Quantity: 2

80/20 1in x 1in Smooth Tri-Slotted Aluminum Extrusion

Length: 17 in

Quantity: 5

80/20 1in x 1in Smooth Tri-Slotted Aluminum Extrusion

Length: 10 1/4 in

Quantity: 2

1” x 1” 10 Series - Black Plastic End Cap

Quantity: 6

Quantity: 100

Black Button Head Socket Cap Screw

Thread Size: 1/4-20

Length: 3/4in

Quantity: 22

Black Button Head Socket Cap Screw

Thread Size: 1/4-20

Length: 1/2in

Quantity: 40

Black Button Head Socket Cap Screw

Thread Size: 1/4-20

Length: 1in

Quantity: 8

1/4 Inch 304 Stainless Steel Spring Washer Split Lock Washers

Quantity: 100

Length: 2in

Quantity: 2

1/4 in.-20 Zinc Plated Tee Nut

Quantity: 2

Aluminum Profile Connector Set

Quantity: 1

Tools You Will Need

Drill

1/4in drill bit

3/4in Forstner Bit

Circular Saw

1/2in drillbit

Metal bender/bench vise

Assembly

Layout the Frame

The first step in the process is to lay out the frame for the top to sit on. For this, we will use the 30in and the 17in extrusions. Layout the 30in extrusions on the outside and the four 17in extrusions on the inside as shown to the left. Try and evenly space out the bars as they will impact where you drill your holes for the top plate assembly.

Once you are happy with the layout add all of your 1/4-20 tnuts into the groves on the frame. Remember that it’s not just the nuts for the frame assembly but the support leg and the top plate & d-rings you need. If you forget this step you will be disassembling the frame.

Assemble the Frame

Assemble the frame using the 90-degree profile connectors at each corner of the frame as shown. For the assembly on the shore sides, remember to space the frame so that the plastic end caps sit flush with the end crossbar. See the video for an example of this. Add the plastic end caps with the provided plastic pressure peg. Top assembly is complete

Drill Through Hole for Tnut

This is the hole that will connect the seat mounts to the seat delete frame. For the 3rd Gen Tacoma this is roughly 1 1/2in in from the end of the extrusion including the end cap for measuring. Use a 1/4in drill bit after punching the hole in the channel of the extrusion and drill through the extrusion completely. Be sure to wear eye protection while drilling as aluminum like to chip when its drilled.

Drill an identical hole on the opposite side of the frame using the same measurements.

Cut the top plate

Using the 2ft x 4ft MDF 1/2in sheet measure your frame width and length to cut the top plate out. For this specific build, the top plate is 19in x 30 1/4in. Double check your measurements of your top even if you are rebuilding this exact seat delete.

Be sure to wear a mask and safety goggles when cutting MDF.

Rout the top edges

This step can be optional but is recommended. On one side of the MDF, route all four edges with a gentle bevel to take the edge off. This will be the very top that the fridge sits on and will help prevent and damage to the top plate or your hands when moving items in and out of the truck.

Again, don’t forget to wear a mask and safety goggles.

Create a layout grid for drilling

On the bottom side of the plate (the side you did not bevel the edges) create a grid pattern for marking the centerline and drill points for the bolts to connect the T-nut, bolts for attaching the top plate to the frame, and the d-ring mounts. Take your time and mark out all of the spots that will be drilled.

Drill & Recess

Once you have the grid laid out in the above step start drilling with a smaller bit first on the bottom side of the plate where your grid is. You can freehand this but I highly recommend a portable drill guide to get that perfect hole through the plate.

Once all of the pilot holes are drilled flip the board so that the top beveled side is facing up and your grid is facing down. On all of the pilot holes, except for the holes that are used to mount the d-rings, use the 3/4in forstner bit to drill a recess for the T-nuts and the bolt assembly to indent the top plate so the bolts sit flush. For the t-nuts, you will go down about 1/16th of an inch. Use a bolt assembly (Bolt + Lock washer + washer) to estimate the depth of the other holes. They are roughly 5/16in deep.

After all of the recesses are made flip the board back over and drill the pilot holes with the 1/4in drill bit all the way through. You may want to try and dry assemble the platform and top at this time to see if you need to widen the 1/4in holes to make assembly easier.

If everything fits, disassemble the top from the frame and paint with a bed liner spray. I recommend leaving the t-nuts in when spraying. just cover the threads if you do so. Reattach the frame to the top once dried.

Assemble Support Legs

Take your time with this when assembling as each truck will vary slightly. Add the leg supports by loosely fitting the remaining two 10 1/4in and 17in extrusions to make a squaty “H” that will be connected to the top frame as shown in the picture. This should be done on the opposite side that you drilled through the top frame.

Take the loosely assembled frame to the truck and attach the top frame to the rear seat factory frame so that the top plate is level in the truck. Push the legs as close to the bottom seat assembly on the rear floor of the cab till they cannot move any further towards the seat and ate perfectly 90 degrees (or close enough) where you can tighten down the leg supports onto the main frame.

Leg Support Cross Bar

This is the trickiest part of the build. Once you have the frame and support legs locked in, measure the distance from the support leg to the location where the lower factory seat bolts into the truck frame. Then bend the 1/4in aluminum flat bar to make up the distance between the seat delete support legs and the truck. I used a 35deg angle on each bend. I would recommend 90 deg for each so you can get 2 bolts in whereas I only was able to get 1. You can use the bench vise or a metal break to bend this aluminum easily.

Once it is bent cut the bar to size and locate where to drill a 1/2in hole for each of the factory bolts to connect the seat delete to the frame. attach with the normal economy tnut slot hardware as shown in the image.

Add D-rings

Add the d-rings to the four corners by using one of the longer screws (Screw + lock washer + washer + d-ring mount) to the frame.

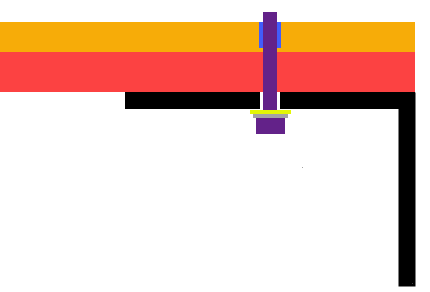

Install Diagram

This will hopefully make sense as per how to attach the seat delete to the rear seat mounts. The black in the diagram to the left represents the factor seat mounts. Bring the seat delete assembled frame into the truck and rest the side without the support legs on top of these factor seat mounts.

Using the 2in 1/4-20 hex bolts (purple) assemble the bolt, 1/4in lock washer (grey), and 1/4in washer (yellow) together. Line up the holes that are drilled in the seat delete frame and feed the bolt through the hole all the way up to the t-nut (blue) that is attached to the top plate on the seat delete. Screw in till tight.

Attache the leg support cross bar using the factory seat hardware to the frame of the truck.